printing on dibond

Printing on dibond Poland is an increasingly popular advertising and decorative solution.

dibond aluminium composite

Dibond is a lightweight yet exceptionally durable composite material, ideal for many applications, including direct printing. It consists of two thin layers of aluminium, typically 0.2–0.3 mm thick, sandwiched between a plastic core (usually polyethylene), sometimes a ceramic core. Thanks to this structure, dibond combines the rigidity of metal with low weight.

The panels are available in various thicknesses – most commonly 2, 3, and 4 mm – allowing them to be tailored to the requirements of a given project. Dibond is ideal for direct UV printing, and its smooth surface ensures high-quality colour reproduction and weather resistance. Some 3 and 4 mm panels meet non-flammability standards, allowing for their wide use in construction. In modern construction, entire building facades are constructed from dibond panels.

Printing on dibond: how does it work?

UV printing involves applying ink directly to the dibond board, followed by simultaneous UV curing. The result is exceptional image quality (colour intensity, sharp detail) and resistance to abrasion and fading. The printed dibond is ready for immediate use, as the curing process is instantaneous.

- Double-sided printing is possible, as well as printing with white ink, which serves as a base for printing on non-white dibond.

- UV prints are easy to maintain – the smooth and durable surface requires no special care.

applications of printing on dibond

Dibond printing is suitable for many industries – here are the most popular:

- outdoor advertising and signage: advertising signs, information boards, building signs, single letters, and light boxes – its durability and aesthetics make dibond a perfect medium for long-term marketing investments;

- indoor and outdoor displays: due to the durability of the print and substrate, printing on aluminium composite is an excellent solution for outdoor graphics;

- exhibition systems: dibond brings lightness, rigidity, and the ability to cut custom shapes to trade show stands and displays – this is used by advertising agencies and event designers;

- interior decoration: paintings, wall panels, and artistic graphics – dibond printing Poland is ideal for offices, galleries, and designer interiors, including elegant, unconventional arrangements, such as brushed silver dibond;

- specialised designs: architectural elements, building facades, equipment housings, technical and rating plates – thanks to mechanical and chemical resistance, resistance to all weather conditions and maintaining dimensional stability.

Why choose printing on dibond?

1. Unrivaled durability:

- very high resistance to weather conditions – rain, UV radiation, wind, frost, and temperature fluctuations do not affect the colour and structure of dibond.

- mechanical resistance – the material does not bend, deform, or corrode, and is resistant to scratches and chemicals.

2. Lightweight and easy installation:

- dibond aluminium composite is much lighter than solid metal sheets, making it easier to transport and install, and allows for use in areas with limited load-bearing capacity.

- dibond is an easy-to-cut, mill, drill, bend, and wrap material – without the need for specialised tools.

3. High-quality UV printing:

- direct UV printing on dibond sheets is characterised by intense, saturated colours and very high detail resolution.

- UV technology guarantees the durability of the graphics – the dibond surface is factory-powder-coated, and the print on it is resistant to fading, moisture, and abrasion.

4. Aesthetics and a variety of finishes:

- dibond is available in matte, glossy, and mirror-brushed finishes (silver, gold), as well as in many RAL colours, allowing you to match the material to your project’s specific needs.

- the smooth, elegant surface enhances the prestige of the final effect – ideal for professional graphics, signs, and light boxes.

printing on dibond: summary

Printing on dibond combines durability, aesthetics, and flexibility — it’s ideal for advertising, interior design, and exhibition systems. UV printing technology makes the print weather-resistant, vibrant, and durable.

Dibond is a composite panel consisting of two thin layers of aluminium bonded with a lightweight polyethylene or ceramic core. This combines the lightness of an aluminium substrate with the strength and rigidity, making it an ideal material for both indoor and outdoor applications.

If you’re planning outdoor advertising or graphics, elegant interior decorations, or durable signage, choosing dDibond with UV printing guarantees quality and a lasting effect.

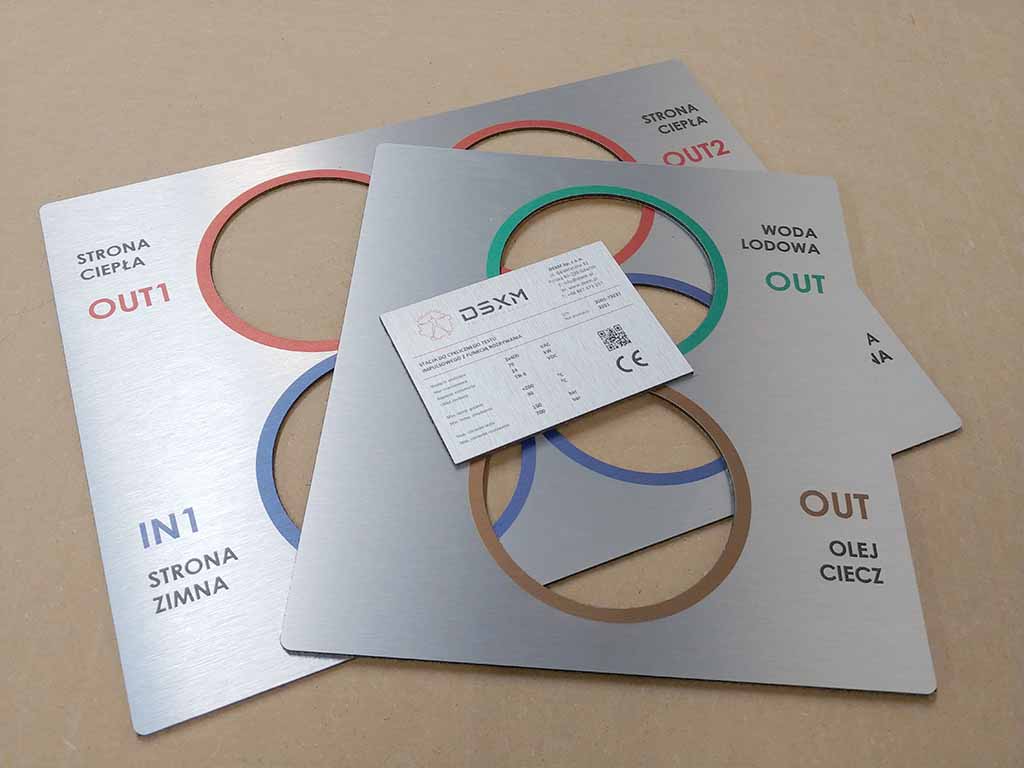

In the photo: test device plates printed using UV technology on brushed dibond. The rounded edges and pipe openings were CNC milled. Local white underprinting is applied to the coloured elements. Dibond printing Poland. Printing on aluminium composite Poland.

See also: dibond signs