printing on polycarbonate

Printing on polycarbonate involves applying graphics to a sheet of polycarbonate, which is a polymer material from the group of carbonic acid polyesters, using UV printing.

Polycarbonate is a modern polymer plastic. Most often used in public places, it is an excellent replacement for glass. It is characterized by: lightness (2 times lighter than glass), transparency comparable to glass (up to 92% for 3 mm plates), 25 times higher impact resistance than glass, application temperature range from -40 to +120 °C, possible protection with an anti-UV layer, flame-retardant (flammability class B1), durability (warranty up to 10 years).

printing on polycarbonate Poland

At B52, we use UV printing to create graphics on polycarbonate of exceptional quality. It’s the ideal material for applications requiring not only aesthetics but also mechanical resistance and safety.

UV printing is a form of printing that uses ultraviolet light to cure ink. The heads distribute the ink on the surface of the material, and specially designed UV lamps follow them immediately, curing the ink. Because this happens very quickly, drops of wet ink do not spill over the surface, which allows you to preserve fine print details. This solution allows printing on polycarbonate, but also on other materials that do not absorb the ink, e.g. on glass, acrylic, metals, ceramics, etc.

Due to the high smoothness of the surface of the material, as in the case of glass, before printing on polycarbonate we cover its surface with an activator (primer). It provides better adhesion and therefore greater durability of printing on polycarbonate.

Printing on polycarbonate is used in many areas where not only the transparency of the substrate is important, but also its unmatched resistance to breakage. It replaces printing on glass where safety of use is required. Unlike acrylic glass, printing on polycarbonate also meets non-flammability standards. Therefore, printing on polycarbonate is used in many areas, such as exhibitions, advertising, packaging production, construction and interior design. Applications include the creation of transparent labels, signs, stickers, displays, control panels, protective covers and decorative elements.

Solid or multi-wall polycarbonate offers unique properties – it’s a virtually safe alternative to glass, while also boasting high impact and weather resistance. UV printing technology allows for direct application of graphics to polycarbonate: the ink is UV-cured, providing resistance to scratches, moisture, and sunlight.

At B52, we use polycarbonate to produce prints, advertisements, single letter signs, information boards, screens, decorative panels, and expressive displays for interiors and exteriors. Wherever exceptional mechanical resistance and fire resistance are essential. We offer CNC milling and spacer mounting as part of our polycarbonate printing services, allowing for a 3D effect and modern design. CNC milling expands the range of UV printing applications. The combined use of these technologies can create a truly unique visual effect.

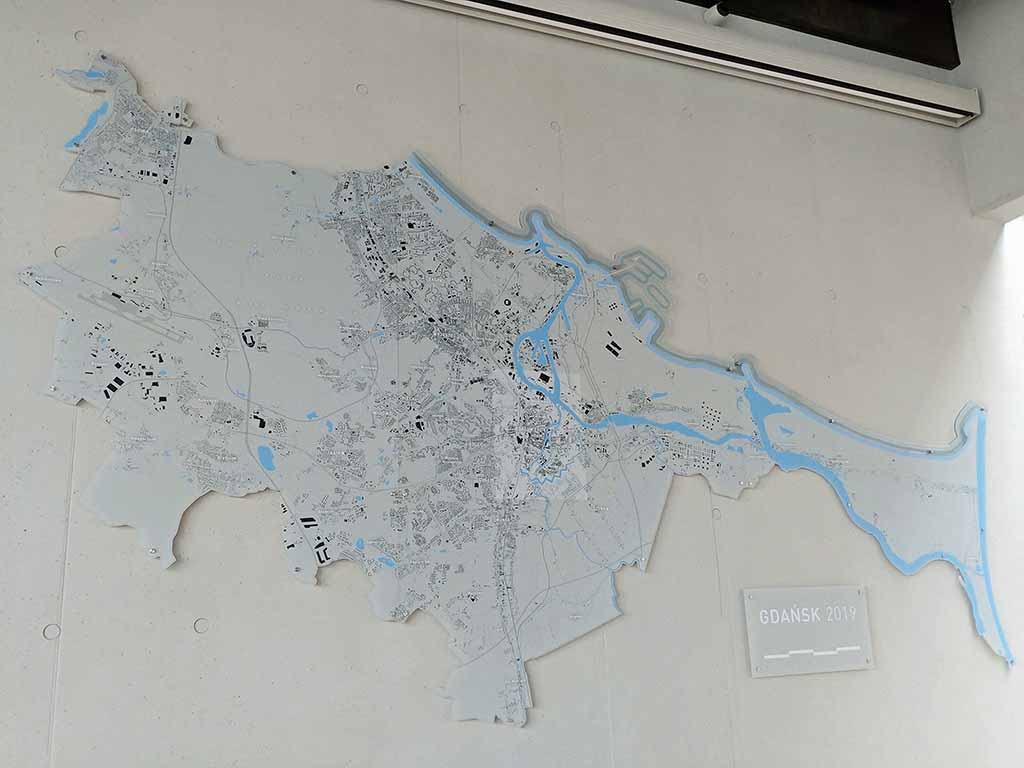

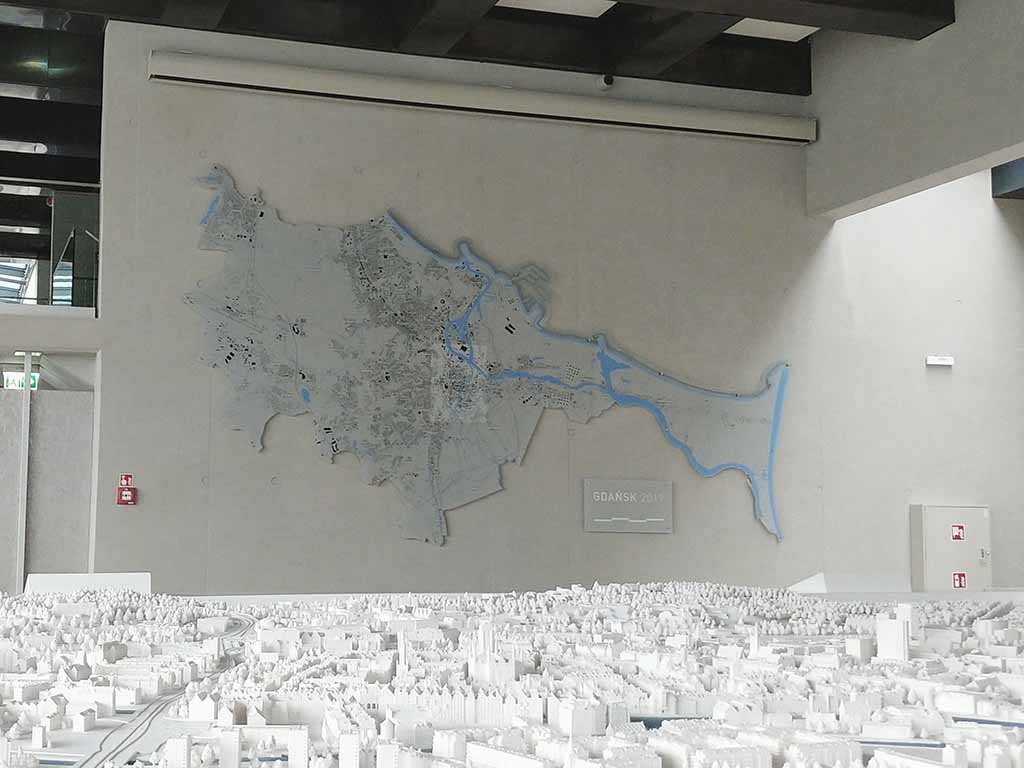

In the photos: map of Gdańsk made in UV printing technique with selective white underprint on transparent polycarbonate with non-flammability standard. CNC Contour milling. Installation on distance pins. Printng on polycarbonate. White colour printing.