white printing

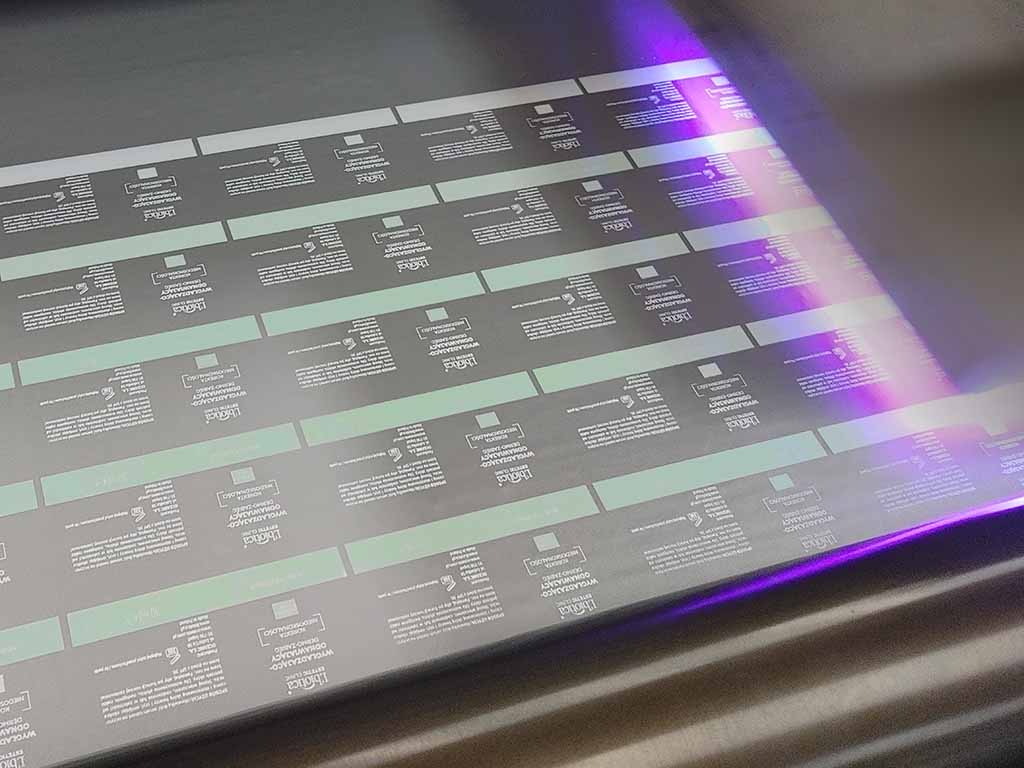

Introducing white ink printing. The use of white printing significantly increases the technical and creative potential, but in order:

In traditional printing, white is not treated as a colour, and white areas are simply not printed. Until recently, the only way to achieve white elements was to resort to a little trick and print everything in colour, leaving the white elements unprinted. However, this solution has many disadvantages: firstly, if we use a white substrate, when printing the background, we have to take care of the analogous printing on the other side. Secondly, anyone who wants to keep small elements sharp when printing in reverse knows how technically challenging this is. Third: we do not always use white substrates.

White printing. White colour printing. White ink printing.

Printing with white ink gives you completely new possibilities.

Firstly, we give you maximum quality and sharpness of even small elements, regardless of the colour of the substrate. A wide range of materials that can be used in UV printing with white colour further expands the range of printing applications. Secondly, selective white underprint when printing on non-white materials (e.g. wood, ecological papers and cardboards) allows you to maintain the fidelity of the given colours. Thirdly: white underprint allows local elimination of colour transparency on transparent materials. Unique labels and stickers on transparent film. Fourthly: exceptionally decorative effect possible in printing only in white colour. Direct white printing on acrylic, glass, wood, ceramics and many other non-white materials.

white ink printing applications

White ink printing is used in many industries:

- Advertising and marketing: in the production of stickers, boards, advertising signs,

- Packaging and labels: ideal for printing on transparent or metallic films, where white ink allows for opacity and contrast effects,

- Decorations and personalisation: printing on wood, glass, ceramics or metal, enabling the creation of unique decorations, plaques or personalised gifts,

- Exhibitions: exceptional effect in printing on non-standard coloured substrates,

- Artistic graphics: implementation of non-standard graphic designs on unusual substrates.

It is worth emphasizing that thanks to white ink it is possible to achieve the effect of “negative printing” on dark surfaces, which increases the versatility of this technology.

How to prepare files for printing with white ink?

The default mode of operation of every printing machine, both large and small, is printing on white substrates. The CMYK space, created for printing, tells the machine where to use the inks and how to mix them. So by default, placing a white area in the file only means for the machine to skip printing in that area and, consequently, leave the substrate colour. However, it is not a signal to use white colour.

In order to achieve the ability to print with white ink, certain rules should be followed when preparing graphic files:

Vector files: you need to create objects filled with a spot colour and name it as “white”. An outline may not be filled with white spot colour. If an object is to be printed in colour as well, the white object must be a copy of it. All white objects should be placed above the other objects (regardless of whether they are to be printed above or below the colour), necessarily with the overprint option turned on.

Bitmap files: you need yo create an additional spot channel and name it as “white”. Then you should fill that channel with colour where needed. The file should be saved in TIFF with the spot channels option selected.

White printing. White colour printing. White ink printing.